Secondary operations service for pressure die casting projects at SuNPe

What is secondary operations?

Secondary operations is the critical last step of the manufacturing process, which can improve the component characteristics, achieve tight tolerance on drawing and brought into alignment with design specifications. At SuNPe, we can offer secondary operations service to help our customer bring their die casting parts to market directly.

Why die casting projects need secondary operations?

After die casting, most die casting products shape characteristics and surface effects are very close to the design requirements. They only need to simply removed the flash.

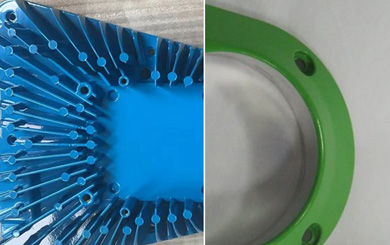

Nevertheless, some die casting products require additional processing after die casting. This occurs when the products have complex characteristics, need tight tolerance and additional surface finishing.

The common secondary operations at SuNPe

Post machining

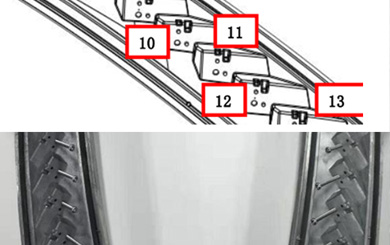

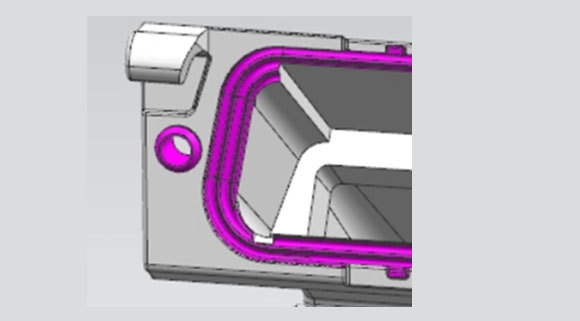

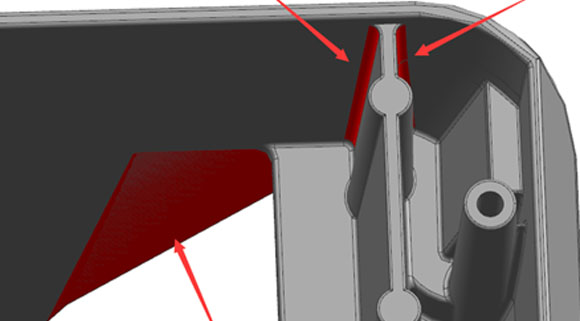

Post machining is one of the important secondary operations, which can help to drill hole and threaded holes and the complex shapes that are often very difficult and inefficient to cast. Also it can make sure the feature and design consistency, because it may need draft angle for de-molding, which will changed the design.

The die casting projects cost and time can be reduced by using post machining.

Drill holes and threaded

We can drill hole and threaded by post-machined after die casting.