SuNPe has ability to manufacture the rigid material products

- designer:

- Types:

- Craft:

- time:2023-04-14 17:29:37

- Pageviews: time

- Service Content:Rigid materials can be particularly difficult to machine due to their difficult to find readily available material and high cost if a part has to be scrapped. The following article will introduce SuNPe has the ability to customize and machine the rigid material such as the tungsten alloy with different proportions of elements for customer.

- Preview:View

Rigid materials can be particularly difficult to machine due to their difficult to find readily available material and high cost if a part has to be scrapped. The following article will introduce SuNPe has the ability to customize and machine the rigid ma

SuNPe has ability to manufacture the rigid material products

Overview:

Rigid materials can be particularly difficult to machine due to their difficult to find readily available material and high cost if a part has to be scrapped. The following article will introduce SuNPe has the ability to customize and machine the rigid ma...

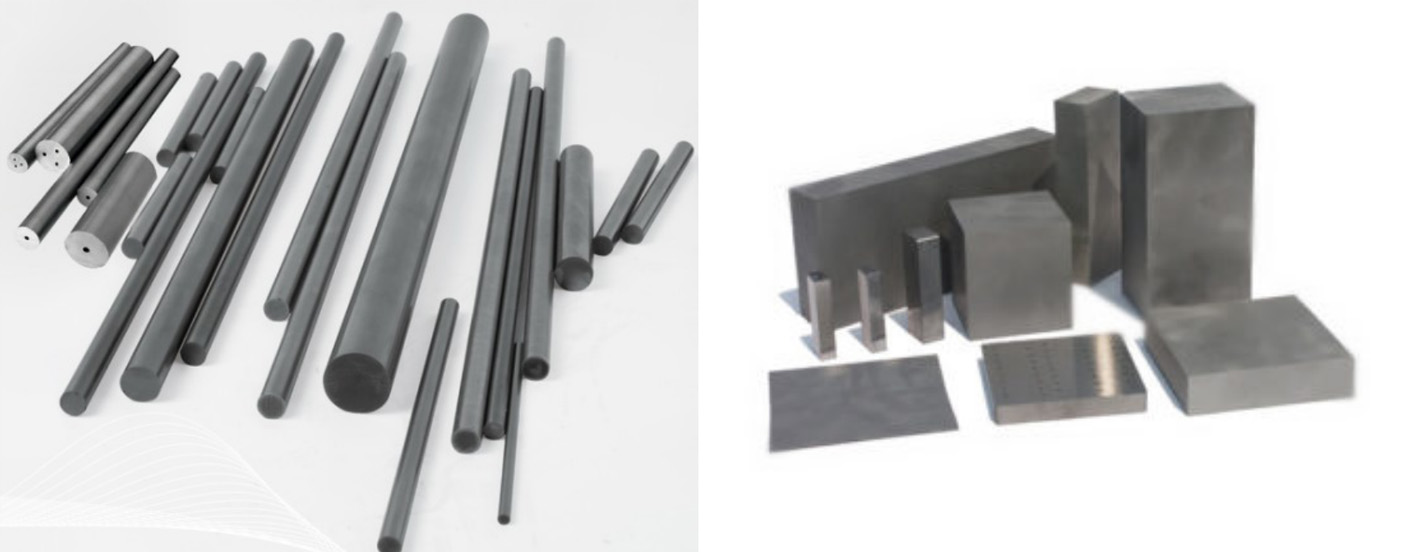

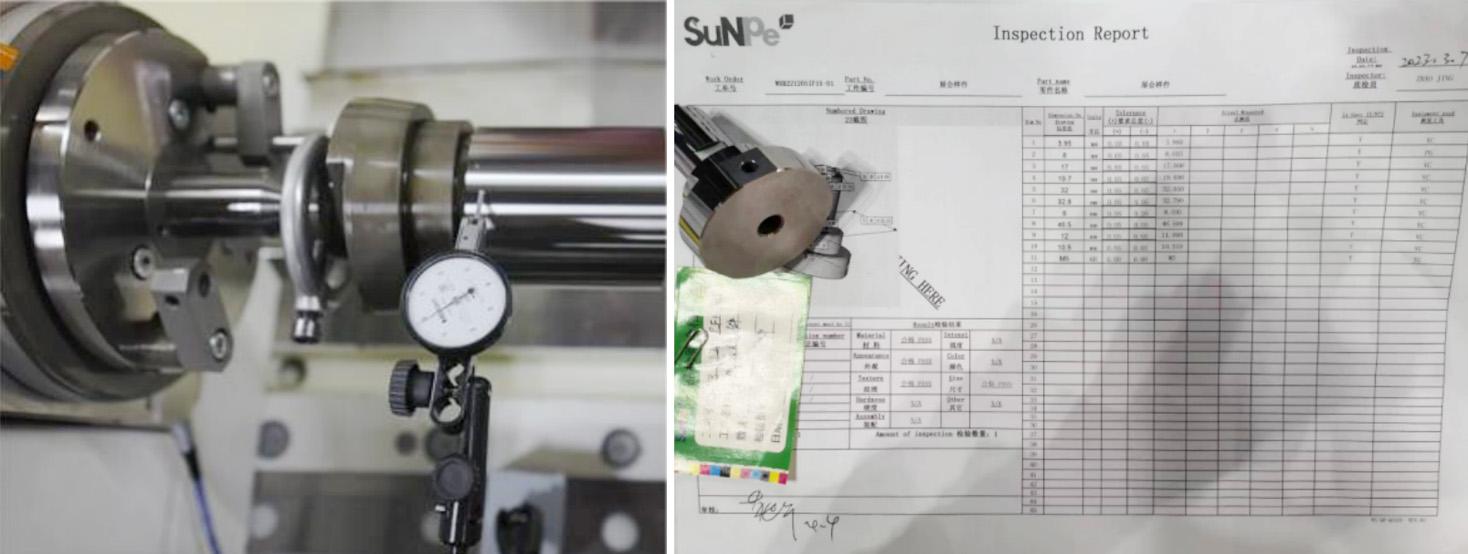

Rigid materials can be particularly difficult to machine due to their difficult to find readily available material and high cost if a part has to be scrapped. The following article will introduce SuNPe has the ability to customize and machine the rigid material such as the tungsten alloy with different proportions of elements for customer.

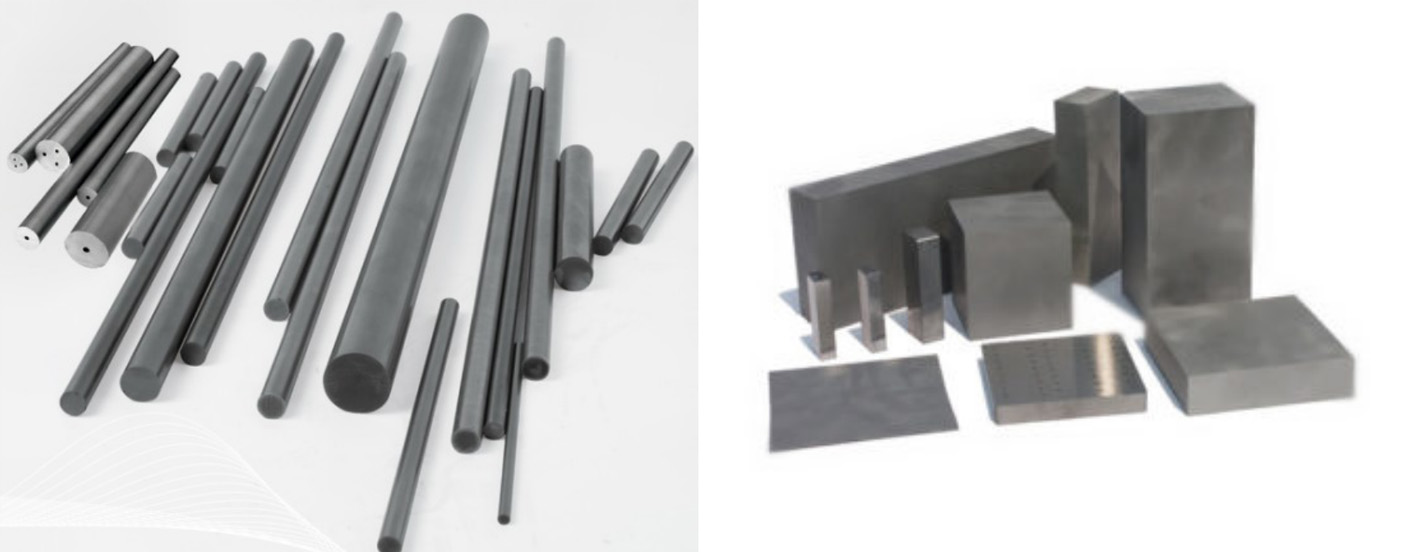

Tungsten Carbide is one of the strongest metals available, making it ideal for a variety of applications. Such as Alloy military products, alloy jewelry, alloy counterweight parts. Nowadays, SuNPe has successfully processed the components in Tungsten Carbide 6% Ni, Tungsten Carbide 10% Ni and Tungsten Carbide--K30. To customize these material we use powder metallurgy to add different rigid carbides or nickel elements to get them. We can customize with different percentage and different elements on the tungsten and make the component basic shape directly by the powder metallurgy. The advantage of this is to save processing cost and processing time.

When compared to other metals, the challenge of machining Tungsten Carbide are characterized by their high strength and brittleness. The hardness of Tungsten Carbide is achieve around HRC89.5 degree.

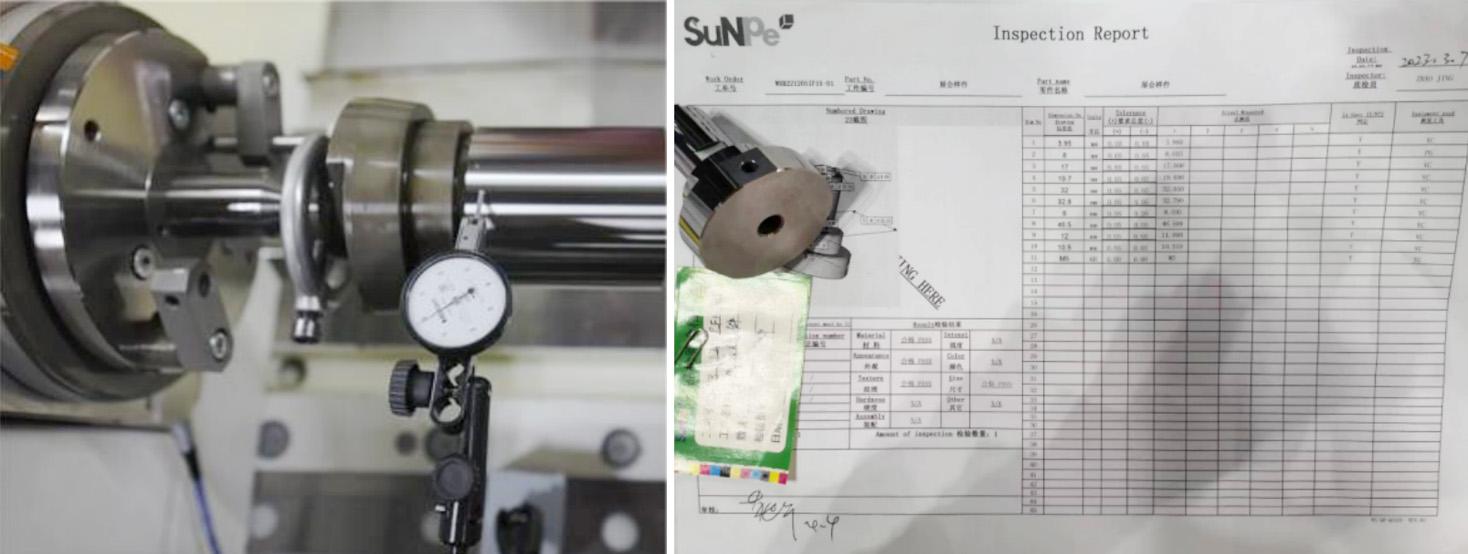

As the hardness of Tungsten is harder than the CNC tools that it cannot be used for CNC milling and with higher rigidness of tungsten increases the cutting force required to remove the material. All of these components look very simple and seem to be processed by CNC turning, but due to the hardness is too hard SuNPe needs to customize as combine with the processing such as CNC grinding, Wire cutting and other processing technical. To achieve the precision and surface roughness required by customer.

If you have any projects with the special material. Welcome feel free to send us for quote. We are happy to provide the unique solutions for your projects!

E-mail: sales@sunpe.com

Tungsten Carbide is one of the strongest metals available, making it ideal for a variety of applications. Such as Alloy military products, alloy jewelry, alloy counterweight parts. Nowadays, SuNPe has successfully processed the components in Tungsten Carbide 6% Ni, Tungsten Carbide 10% Ni and Tungsten Carbide--K30. To customize these material we use powder metallurgy to add different rigid carbides or nickel elements to get them. We can customize with different percentage and different elements on the tungsten and make the component basic shape directly by the powder metallurgy. The advantage of this is to save processing cost and processing time.

When compared to other metals, the challenge of machining Tungsten Carbide are characterized by their high strength and brittleness. The hardness of Tungsten Carbide is achieve around HRC89.5 degree.

As the hardness of Tungsten is harder than the CNC tools that it cannot be used for CNC milling and with higher rigidness of tungsten increases the cutting force required to remove the material. All of these components look very simple and seem to be processed by CNC turning, but due to the hardness is too hard SuNPe needs to customize as combine with the processing such as CNC grinding, Wire cutting and other processing technical. To achieve the precision and surface roughness required by customer.

If you have any projects with the special material. Welcome feel free to send us for quote. We are happy to provide the unique solutions for your projects!

E-mail: sales@sunpe.com