Case Studies

-

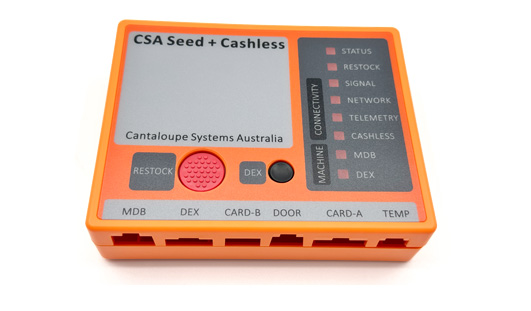

SuNPe provides convenience for various industries and has produced many customized products in the market including many assemblies, achieveing win-win with our cutomers.

SuNPe provides convenience for various industries and has produced many customized products in the market including many assemblies, achieveing win-win with our cutomers.

-

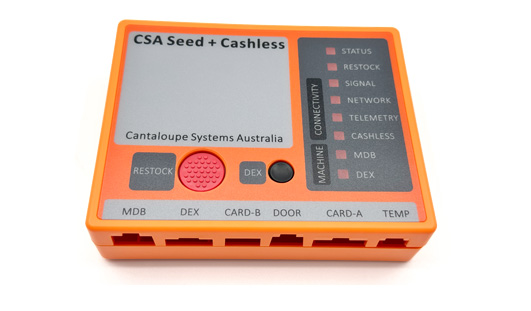

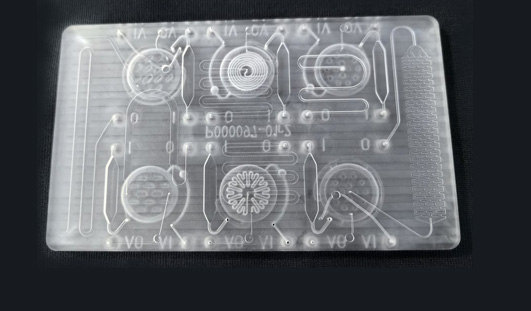

We have a rich expensive to machine the tiny feature, here is a case showing how we machine tiny slots of clear part and keep good surface roughness without sanding or polishing.

We have a rich expensive to machine the tiny feature, here is a case showing how we machine tiny slots of clear part and keep good surface roughness without sanding or polishing.

-

SuNPe helps the collar project to level up pasture management. SuNPe has not only made great achievements in automotive, home appliance, medical, electronic , smart robot and industrial products ,etc., but also in agricultural civilization. With professional techniques and huge capacity, we can help to handle and manage well the whole project for customers. The case of collar will show how we can help with your projects.

SuNPe helps the collar project to level up pasture management. SuNPe has not only made great achievements in automotive, home appliance, medical, electronic , smart robot and industrial products ,etc., but also in agricultural civilization. With professional techniques and huge capacity, we can help to handle and manage well the whole project for customers. The case of collar will show how we can help with your projects.

-

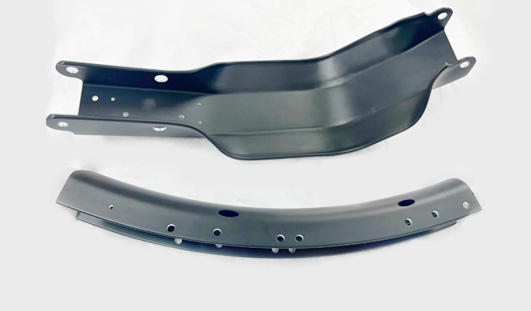

SuNPe have great experience on tooling and injection parts, not only simple ABS parts, but also making good injection parts in high strength material such as nylon, POM, PPS+GF and others.

SuNPe have great experience on tooling and injection parts, not only simple ABS parts, but also making good injection parts in high strength material such as nylon, POM, PPS+GF and others.

-

SuNPe have done Custom plastic injection molding projects for various industries including medical, automotive, electronics, consumer products with more than 10 years of experience, we can offer a complete solution that covers every aspect of different materials, tool making, part fabrication, finishing, and final inspection.

SuNPe have done Custom plastic injection molding projects for various industries including medical, automotive, electronics, consumer products with more than 10 years of experience, we can offer a complete solution that covers every aspect of different materials, tool making, part fabrication, finishing, and final inspection.

-

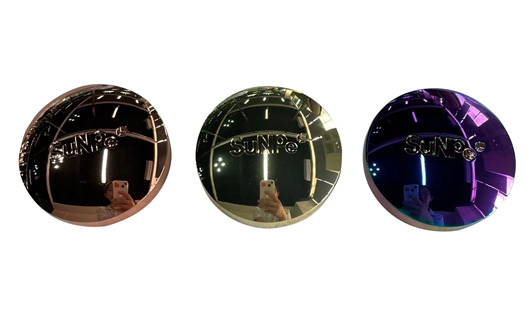

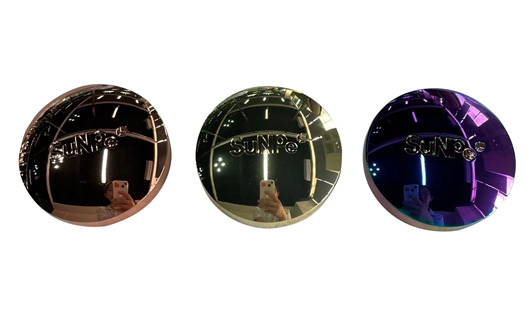

SuNPe provides chrome plating surface treatment service, it often used in some auto parts, industrial tools, electronic products and accessories, etc. Chrome plating has decoration, anti-corrosion, wear-resisting functions.

SuNPe provides chrome plating surface treatment service, it often used in some auto parts, industrial tools, electronic products and accessories, etc. Chrome plating has decoration, anti-corrosion, wear-resisting functions.

-

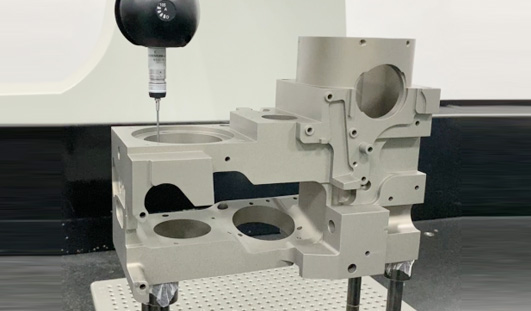

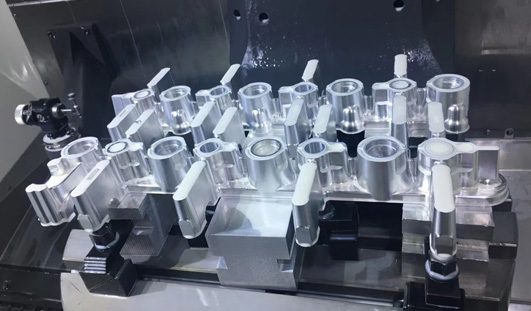

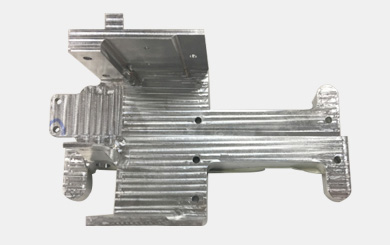

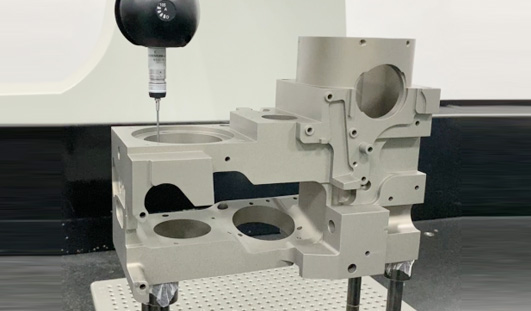

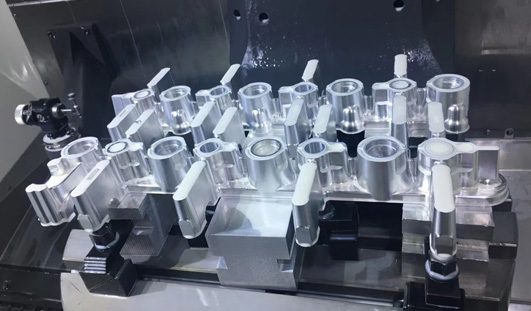

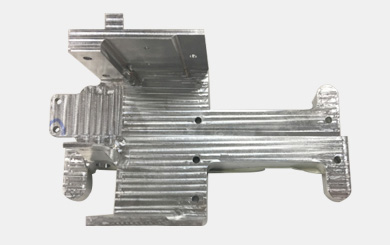

With professional techniques and huge capacity, we can help to handle and manage well the whole project for customers. SuNPe helped this Aluminum crane project from prototype to low-volume production for 4-axis CNC machining with hard anodized finish. Moreover, we done CMM inspection to confirm every dimension under control.

With professional techniques and huge capacity, we can help to handle and manage well the whole project for customers. SuNPe helped this Aluminum crane project from prototype to low-volume production for 4-axis CNC machining with hard anodized finish. Moreover, we done CMM inspection to confirm every dimension under control.

-

Rigid materials can be particularly difficult to machine due to their difficult to find readily available material and high cost if a part has to be scrapped. The following article will introduce SuNPe has the ability to customize and machine the rigid material such as the tungsten alloy with different proportions of elements for customer.

Rigid materials can be particularly difficult to machine due to their difficult to find readily available material and high cost if a part has to be scrapped. The following article will introduce SuNPe has the ability to customize and machine the rigid material such as the tungsten alloy with different proportions of elements for customer.

-

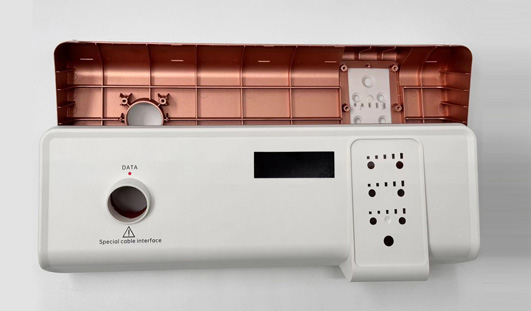

At SuNPe, we make this coffee machine that requires different metal and plastic materials and techniques with our comprehensive one-stop services for our customer. Cosmetic surfaces and texture feel are important for this coffee machine. Moreover, we offered assembly service for this project.

At SuNPe, we make this coffee machine that requires different metal and plastic materials and techniques with our comprehensive one-stop services for our customer. Cosmetic surfaces and texture feel are important for this coffee machine. Moreover, we offered assembly service for this project.

-

SuNPe provides high-precision turning parts and one-stop service from prototype to low-volume production.

SuNPe provides high-precision turning parts and one-stop service from prototype to low-volume production.

-

For SLS parts, we not only do in rigid material, but also in soft material. We also can help customers do different surface finishing, such as sandblasting, primer, painting, plating, dying, etc..

2.SuNPe provide one-stop services from prototyping to low-volume production in CNC machining, vacuum casting, sheet metal, injection molding, extrusion, 3D printing. Customer focus, quality first are always our principles.

For SLS parts, we not only do in rigid material, but also in soft material. We also can help customers do different surface finishing, such as sandblasting, primer, painting, plating, dying, etc..

2.SuNPe provide one-stop services from prototyping to low-volume production in CNC machining, vacuum casting, sheet metal, injection molding, extrusion, 3D printing. Customer focus, quality first are always our principles.

-

We can ship the parts with FedEx/DHL/UPS express in 3-5 days. Besides these express ways, for the large production projects, we also can ship the parts by air, boat, or by train. Multiple transportation ways available.

We also can we also can provide one-stop services for metal printing. The surfaces are very rough for the finished parts. So in order to ensure customer get the final appearance they need, we also provide surface finishing service to meet the customers’ need.

We can ship the parts with FedEx/DHL/UPS express in 3-5 days. Besides these express ways, for the large production projects, we also can ship the parts by air, boat, or by train. Multiple transportation ways available.

We also can we also can provide one-stop services for metal printing. The surfaces are very rough for the finished parts. So in order to ensure customer get the final appearance they need, we also provide surface finishing service to meet the customers’ need.

-

SuNPe has rich experience and provided successful and professional solutions in many industries for prototypes and volume production projects, which can help clients manufacture the parts accurately and achieve what they need in time.

SuNPe has rich experience and provided successful and professional solutions in many industries for prototypes and volume production projects, which can help clients manufacture the parts accurately and achieve what they need in time.

-

SuNPe can combine multiple processes to make your unique design come to reality.

SuNPe can combine multiple processes to make your unique design come to reality.

-

With professional techniques and huge capacity, we can help to handle and manage well the whole project for customers.

Our customer work from one prototype to low volume from us for the fast lead time and cost effective.We send our quote within one day and send products in high quality in short lead time

And we take good care of the drawing highlighted O-Ring groove “CNC to have best ability”,we can CNC Machine to achieve customer’s different surface roughness directly,no handwork needed and make sure of the assembly sealing requirements as request.

With professional techniques and huge capacity, we can help to handle and manage well the whole project for customers.

Our customer work from one prototype to low volume from us for the fast lead time and cost effective.We send our quote within one day and send products in high quality in short lead time

And we take good care of the drawing highlighted O-Ring groove “CNC to have best ability”,we can CNC Machine to achieve customer’s different surface roughness directly,no handwork needed and make sure of the assembly sealing requirements as request.

-

With sufficient in-house capacity and rich experience of complicated machining, we’re professional to make your design ideas a reality with high accuracy and great appearance. Here is a case showing how a complicated part with o-ring groove completed at SuNPe.

With sufficient in-house capacity and rich experience of complicated machining, we’re professional to make your design ideas a reality with high accuracy and great appearance. Here is a case showing how a complicated part with o-ring groove completed at SuNPe.

-

In the process of taking a product from idea to functional test, market test and mass production, engineers and designers are always faced with the challenges of tight lead-time, high cost and difficult communication. Manufacturers and design teams are increasingly looking for suppliers that can provide service from prototype to production. SuNPe has a huge capacity to help your project from prototype to production and help to accelerate your new product development and time to market.

In the process of taking a product from idea to functional test, market test and mass production, engineers and designers are always faced with the challenges of tight lead-time, high cost and difficult communication. Manufacturers and design teams are increasingly looking for suppliers that can provide service from prototype to production. SuNPe has a huge capacity to help your project from prototype to production and help to accelerate your new product development and time to market.

-

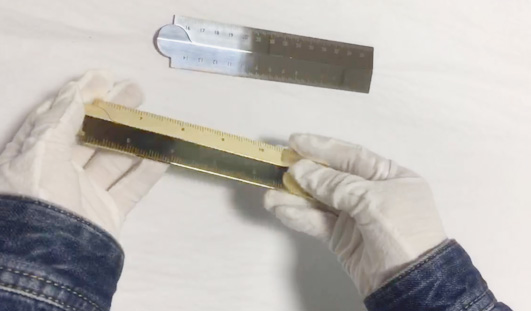

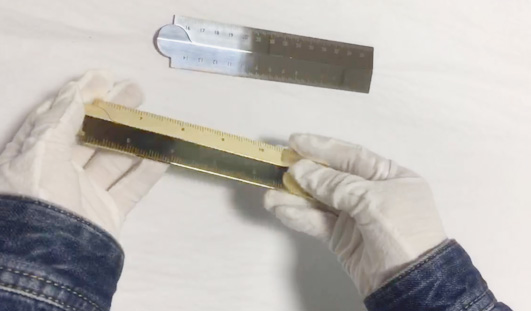

SuNPe provides CNC machining, high polish, and laser engraving services for custom rulers for surface showing and functional testing. It is required to show the effect of two different materials, including stainless steel and brass, mirror surface, and precise scale, producing the slick fit.

SuNPe provides CNC machining, high polish, and laser engraving services for custom rulers for surface showing and functional testing. It is required to show the effect of two different materials, including stainless steel and brass, mirror surface, and precise scale, producing the slick fit.

-

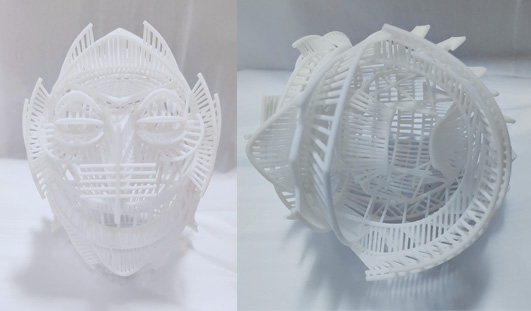

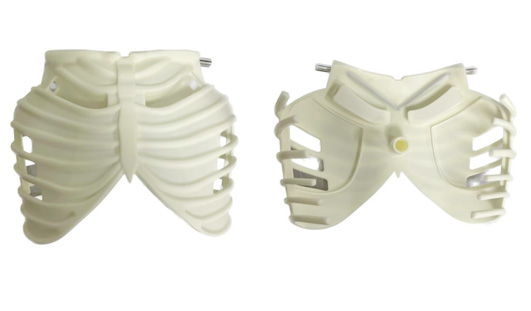

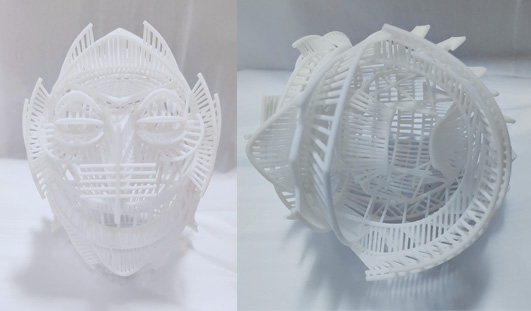

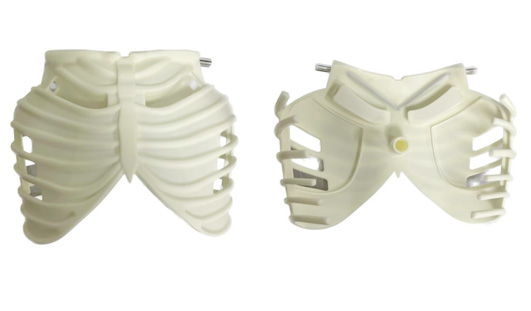

A case for skeletal rib cage model, which is widely used in medical training, manikins and simulators. The services we used for this project is vacuum casting over-molding technology.

A case for skeletal rib cage model, which is widely used in medical training, manikins and simulators. The services we used for this project is vacuum casting over-molding technology.

-

With less cost and time, SuNPe can help you produce different texture on prototype stage, which can help company establish its brand identity, realize its visual marketing and make your product more outstanding and more popular in the market.

With less cost and time, SuNPe can help you produce different texture on prototype stage, which can help company establish its brand identity, realize its visual marketing and make your product more outstanding and more popular in the market.

-

SuNPe has been developing new high-tech surface post-treatment, always looking for higher-end metal surface post-treatment, to provide customers with the best service, we can provide with micro-arc oxidation service. Micro-arc oxidation is an advanced version of anodize, which has a better coating. It is a surface ceramic technology. The principle is that through arc discharge, under the action of instantaneous high temperature and high pressure, through the matching adjustment of the electrolyte and the corresponding electrical parameters, A ceramic film layer dominated by matrix metal oxide was grown on the metal surface.

SuNPe has been developing new high-tech surface post-treatment, always looking for higher-end metal surface post-treatment, to provide customers with the best service, we can provide with micro-arc oxidation service. Micro-arc oxidation is an advanced version of anodize, which has a better coating. It is a surface ceramic technology. The principle is that through arc discharge, under the action of instantaneous high temperature and high pressure, through the matching adjustment of the electrolyte and the corresponding electrical parameters, A ceramic film layer dominated by matrix metal oxide was grown on the metal surface.

-

SuNPe helped produce an art object, the part have many different spikey on the surface, so how does SuNPe make it and achieve the perfect surface?

Multi-axis metal CNC machine tools do not need to fix the mold, highly flexible, high precision. We have 3 axis, 4 axis, 5 axis machine, can meet the machining demand.

SuNPe helped produce an art object, the part have many different spikey on the surface, so how does SuNPe make it and achieve the perfect surface?

Multi-axis metal CNC machine tools do not need to fix the mold, highly flexible, high precision. We have 3 axis, 4 axis, 5 axis machine, can meet the machining demand.

-

Quick turnaround to meet urgent timeline

DFM provided in one day

Tooling finished in 10 working days.

1000 products finished in 4-6 working days.

Quick turnaround to meet urgent timeline

DFM provided in one day

Tooling finished in 10 working days.

1000 products finished in 4-6 working days.

-

SuNPe specialized in prototyping, CNC machining and manufacturing over 18 years, we’ve provided a lot of successful professional solutions to our customers in scientific instrument industry.

SuNPe specialized in prototyping, CNC machining and manufacturing over 18 years, we’ve provided a lot of successful professional solutions to our customers in scientific instrument industry.

-

keyboard will probably be used in any harsh conditions, so we need to apply metal material and hard surface finishing make it protective. First, we used CNC manufacturing to cut the shape and features out of Al 6063-T6 and remain perfect dimensions and natural finish, and then we do Black Hard Anodizing for the surface, finally we finished this keyboard with hard faces that is corrosion-proof and scratch resistant.

keyboard will probably be used in any harsh conditions, so we need to apply metal material and hard surface finishing make it protective. First, we used CNC manufacturing to cut the shape and features out of Al 6063-T6 and remain perfect dimensions and natural finish, and then we do Black Hard Anodizing for the surface, finally we finished this keyboard with hard faces that is corrosion-proof and scratch resistant.

-

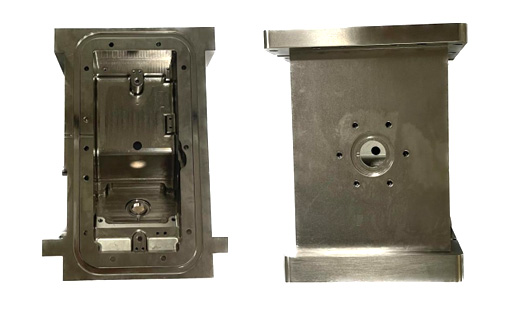

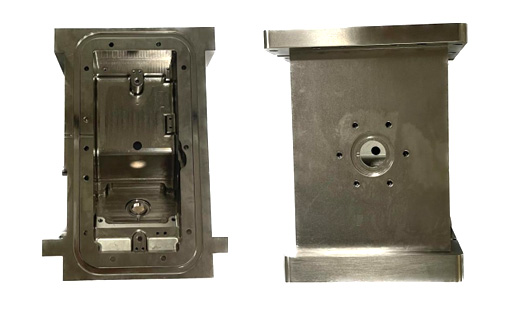

SuNPe makes great tools for prototyping and low-volume production to meet customer’s requirement of different industries. And to better achieve shorten lead-time and cost effective purpose, we have two solution of rapid tooling and production tooling for different requirements.

SuNPe makes great tools for prototyping and low-volume production to meet customer’s requirement of different industries. And to better achieve shorten lead-time and cost effective purpose, we have two solution of rapid tooling and production tooling for different requirements.

-

SuNPe can do high precise projects with tight tolerance 0.01mm by 5 axis CNC from prototype to low volume production and check full dimensions by CMM.

SuNPe can do high precise projects with tight tolerance 0.01mm by 5 axis CNC from prototype to low volume production and check full dimensions by CMM.

-

At SuNPe, a gorgeous looking parts can be achieved by CNC machining and surface finishing, which is made of PMMA with dip dyeing and high mirror polishing.

At SuNPe, a gorgeous looking parts can be achieved by CNC machining and surface finishing, which is made of PMMA with dip dyeing and high mirror polishing.

-

SuNPe used a good way to assemble aluminum part and thin, flexible plastic with beautiful cosmetic surfac and good fitness by vacuum casting over-molding process.

SuNPe used a good way to assemble aluminum part and thin, flexible plastic with beautiful cosmetic surfac and good fitness by vacuum casting over-molding process.

-

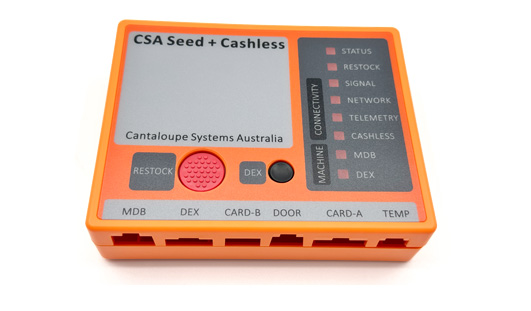

SuNPe helped for a low volume production and assembly alarm system project, which got good feedback from clients.

SuNPe helped for a low volume production and assembly alarm system project, which got good feedback from clients.

-

Those who are familiar with SuNPe should know that we have rich experience in the fields of automotive, medical equipment and home appliances fields, but we also have a lot of experience in prototyping and low-volume production in other fields, such as the Soil Probe Project we are going to study now.

Those who are familiar with SuNPe should know that we have rich experience in the fields of automotive, medical equipment and home appliances fields, but we also have a lot of experience in prototyping and low-volume production in other fields, such as the Soil Probe Project we are going to study now.

-

One typical customized box from prototyping to low volume production,which use for BENTLEY car and provided unique products for customer who has special needs.

One typical customized box from prototyping to low volume production,which use for BENTLEY car and provided unique products for customer who has special needs.

-

we helped produce an innovative nasal speculum.This is an innovation that has led to a more efficient way for doctors to work.

we helped produce an innovative nasal speculum.This is an innovation that has led to a more efficient way for doctors to work.

-

Our company SuNPe has produced barcode verifier for our client, which help deliver the products to market in short time.

Our company SuNPe has produced barcode verifier for our client, which help deliver the products to market in short time.

-

Subject : The Kinetic Reflex

Service: Injection Molding

Subject : The Kinetic Reflex

Service: Injection Molding

-

CNC, Die casting, Surface finish ( Powder coating matching the effect of bark) ,Assembly, Testing, Packing and Delivery

CNC, Die casting, Surface finish ( Powder coating matching the effect of bark) ,Assembly, Testing, Packing and Delivery

-

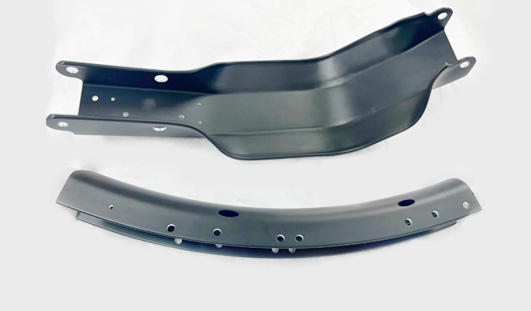

CNC machining, Laser cut&Sheet metal&Riveting, Vacuum casting, Lathe.Also supply fasteners, assemble, packaging and delivery.

CNC machining, Laser cut&Sheet metal&Riveting, Vacuum casting, Lathe.Also supply fasteners, assemble, packaging and delivery.

-

Prototyping, injection tooling service, assemble ,packing and deliver.

Prototyping, injection tooling service, assemble ,packing and deliver.

-

CNC Milling, Turning, Mirror Polished, 2K Clear Lacquer

CNC Milling, Turning, Mirror Polished, 2K Clear Lacquer

-

5-axis CNC Milling, Machined finish, More economical packing services.

5-axis CNC Milling, Machined finish, More economical packing services.

-

CNC Machining, die casting, Injection tooling service, sheet metal, lathe, laser etch, surface finish(polishing, plating, baking paint, gold blocking), assemble, packaging and delivery

CNC Machining, die casting, Injection tooling service, sheet metal, lathe, laser etch, surface finish(polishing, plating, baking paint, gold blocking), assemble, packaging and delivery

-

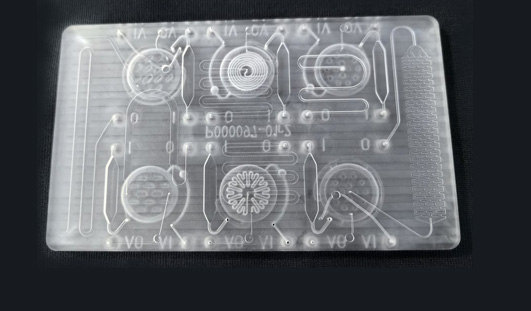

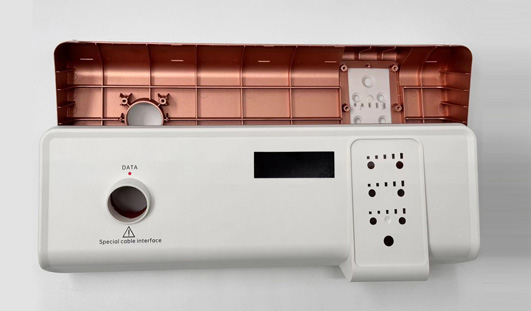

2.1 This product is cosmetic with silkscreen logo and instruction signs.

2.2 Cannot have obvious welding line on surfaces.

2.3 Handle position must be smooth and ensure the strength.

2.4 Blue marks show the instruction signs, assembled with holes on enclosure.

2.1 This product is cosmetic with silkscreen logo and instruction signs.

2.2 Cannot have obvious welding line on surfaces.

2.3 Handle position must be smooth and ensure the strength.

2.4 Blue marks show the instruction signs, assembled with holes on enclosure.