How Does Sheet Metal Fabrication Help In Real Life ?

How Does Sheet Metal Fabrication Help In Real Life ?

Sheet metal parts are known for their strength and durability, it can be applied in various industries, like home appliances, automotive industry, healthcare and medical device etc.

Sheet Metal In Home appliance

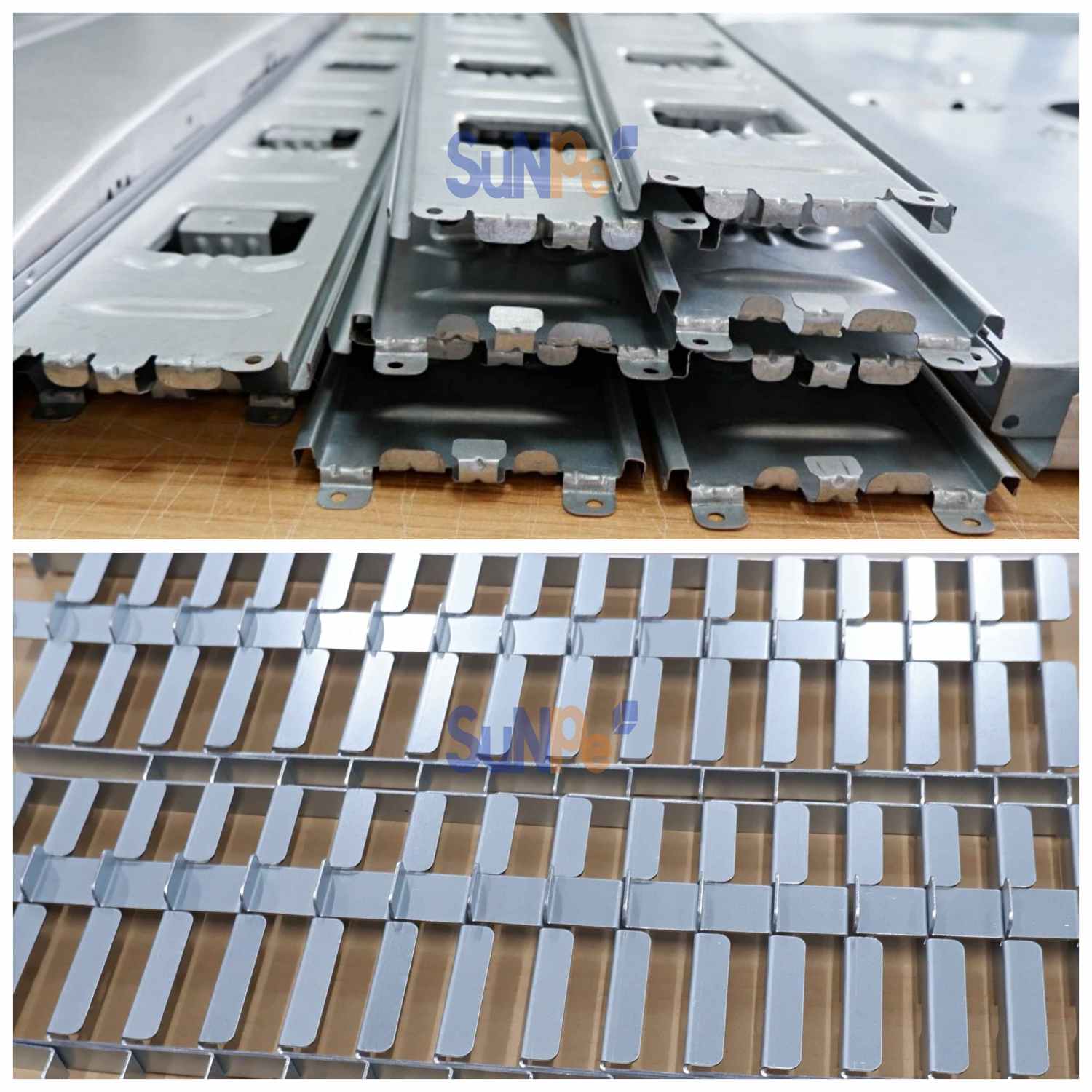

Home appliance products have a huge demand for sheet metal fabrication, for example: the stamping panel for washing machine and refrigerator, metal pressing for washer stand. For those small batches of sheet metal parts, we were made simple mold out of bakelite, metal stamping and metal pressing the parts.Sheet metal fabrication will shorten the lead time and save the cost from prototyping to mass production. During the growing demand of smart homes, this has bought time for the rapid launch of new products and customer-facing.

Sheet Metal In Automotive industry

Carbon neutrality and carbon peaking are the hot topics this year, electric vehicles plays an important part in shaping low-carbon, energy conservation and environmental protection trip mode. Sheet metal manufacturing provides opportunities for the electric vehicle industry to produce high-quality and light-weight components, like metal stamping latch, metal stamping car door, metal pressing battery case housing.

Sheet Metal Capacity at SuNPe

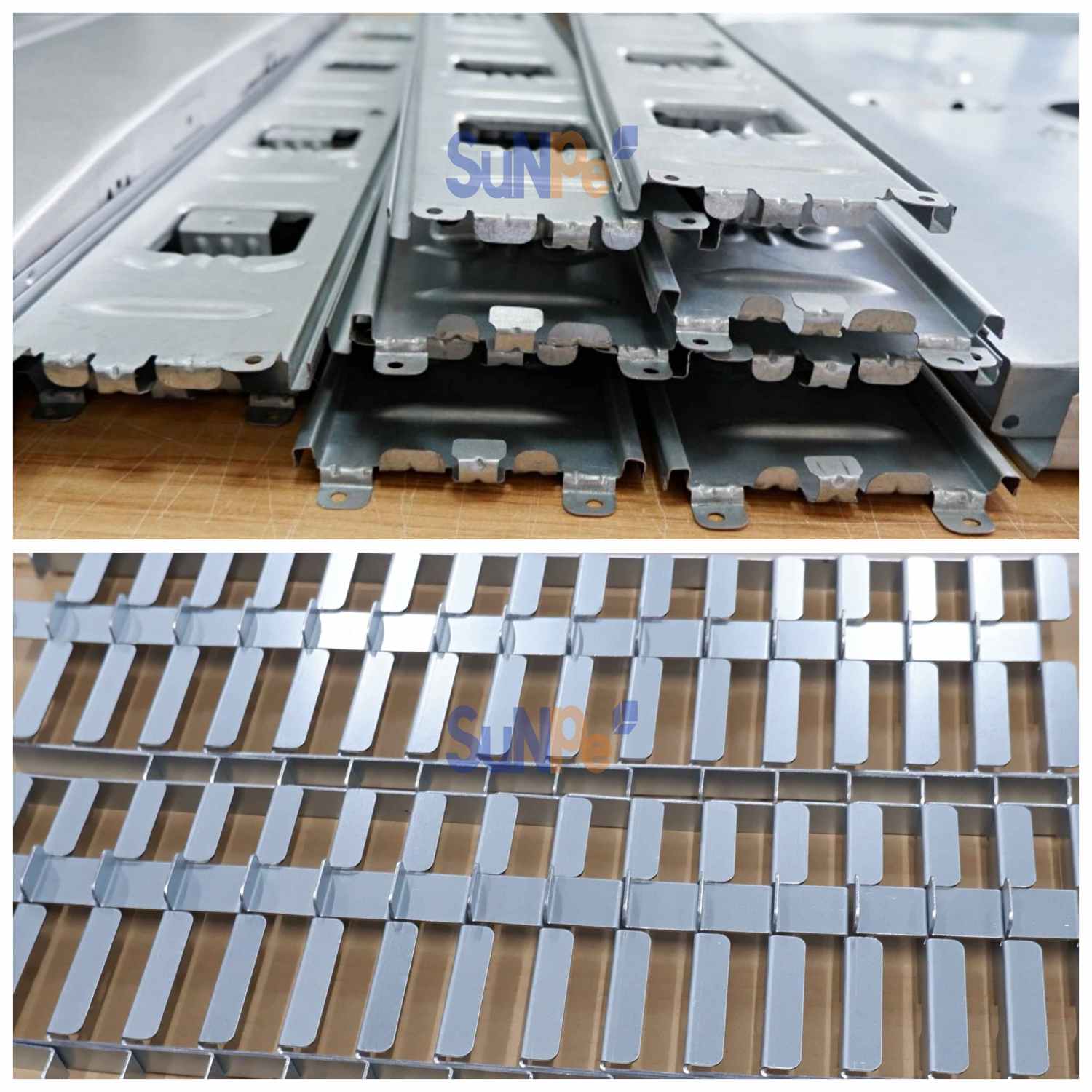

To meet the increasing needs of customer , SuNPe keep developing bending service with various advanced equipments ,like bending, stamping, and laser cutting. SuNPe continuously expand production capacity and improve the technology and processes.

So far, SuNPe has strong ability to process sheet metal parts from prototyping to low volume production, Fully meet the needs of customers for various sheet metal projects in different sheet metal materials.

Sheet Metal In Home appliance

Home appliance products have a huge demand for sheet metal fabrication, for example: the stamping panel for washing machine and refrigerator, metal pressing for washer stand. For those small batches of sheet metal parts, we were made simple mold out of bakelite, metal stamping and metal pressing the parts.Sheet metal fabrication will shorten the lead time and save the cost from prototyping to mass production. During the growing demand of smart homes, this has bought time for the rapid launch of new products and customer-facing.

Sheet Metal In Automotive industry

Carbon neutrality and carbon peaking are the hot topics this year, electric vehicles plays an important part in shaping low-carbon, energy conservation and environmental protection trip mode. Sheet metal manufacturing provides opportunities for the electric vehicle industry to produce high-quality and light-weight components, like metal stamping latch, metal stamping car door, metal pressing battery case housing.

Sheet Metal Capacity at SuNPe

To meet the increasing needs of customer , SuNPe keep developing bending service with various advanced equipments ,like bending, stamping, and laser cutting. SuNPe continuously expand production capacity and improve the technology and processes.

So far, SuNPe has strong ability to process sheet metal parts from prototyping to low volume production, Fully meet the needs of customers for various sheet metal projects in different sheet metal materials.

Other news

- 1Anodizing finishing at SuNPe

- 2Heat Resistant Plastic: How to choose the right plastic for high temperature projects?

- 3Capabilities For Injection Mold Enlarge Again!

- 4SuNPe Wishes You And Your Family A Happy Mid Autumn Festival!

- 5New advanced machines introduced again to the plant 3 of SuNPe

- 6The third basketball league of SuNPe Group in 2020

- 7How does SuNPe help with painting?

- 8SuNPe held a high-lever speech election for the management representative and excellent staff.

- 9How does SuNPe help with surface texture?

- 10UV Coating at SuNPe