How many polishing methods in the surface finishing?

How many polishing methods in the surface finishing?

At SuNPe, we can offer a wide variety of surface finishing like polishing, sandblasting, Anodizing, painting, electroplating and so on.

Do you know how many methods to polish? Now let's talk about polishing.

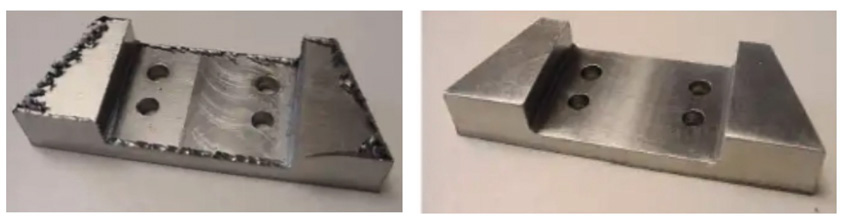

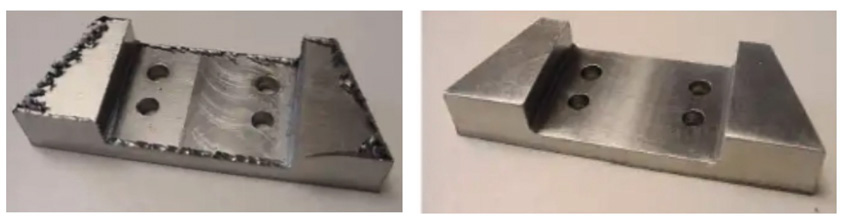

(Before the tumbling) (After the tumbling)

(Tumbling finish)

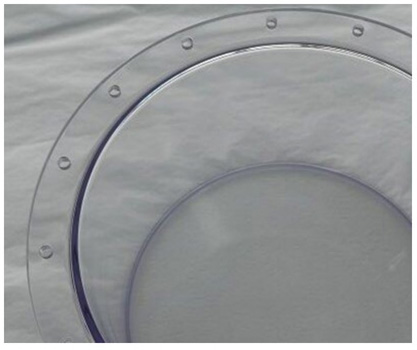

(CNC machined with PC part)

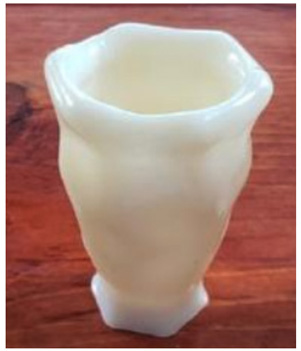

(3D printing part)

(Copper part with Chemical polishing)

Advantages of electro polishing :

1)The inner and outer surfaces have the same color and lustre, and the luster is long-lasting, and the recesses that cannot be thrown by mechanical polishing can also be leveled.

2)High productivity.

3)Increase the corrosion resistance of the part surface.

(Steel part with electrolytic polishing)

These are the common polishing methods, if you want to learn more about the surface finishing, please feel free to contact us.

Do you know how many methods to polish? Now let's talk about polishing.

1.Mechanical polishing-CNC machining part

Mechanical polishing is a polishing method by use some CNC machining tools cut the surface of the material to get a smooth surface. We can also use nylon cloth, wool wheels, sandpaper, etc. to achieve a smooth finish by hand.2. Tumbling –Lathe part and CNC machining part

Tumbling is the use of a horizontal roller in which the part is placed and rolled repeatedly using sand or ceramic fragments. Tumbling is suitable for deburring, degusting, chamfering and bright polishing of various parts of metal, non-ferrous and non-metallic products. It is especially suitable for surface finish machining of easily deformed parts. The advantage is a small amount of manual operation and low cost.

(Before the tumbling) (After the tumbling)

(Tumbling finish)

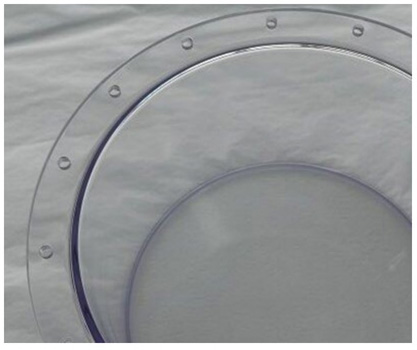

3. Fumigation/vapor polishing-CNC machined transparent part

CNC machined PC and PMMA part, vapor polishing can make them transparent as a surface finish method. It works by heating the fumigant, putting the part in the steam, and the part becomes transparent.

(CNC machined with PC part)

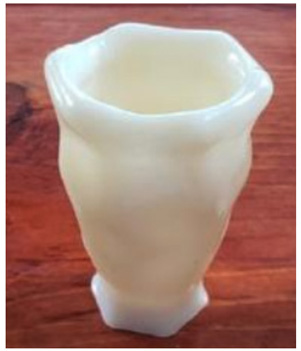

4. Vapor Smoothing-3D printing part

The 3D printed parts are dipped in steam tanks with liquids that have reached boiling point at the bottom. The rising vapor can melt a layer of about 2 microns on the surface of the part, turning it bare and shiny in seconds. Vapor smoothing technology is widely used in consumer electronics, prototyping and medical applications.

(3D printing part)

5. Chemical polishing-CNC machining metal part

Chemical polishing is to make the microscopically protruding part of the material dissolve preferentially over the concave part in the chemical medium, so as to obtain a smooth surface. The main advantage of this method is that it does not need complex equipment, can polish part with complex shapes, and can polish many parts at the same time, with high efficiency.

(Copper part with Chemical polishing)

6. Electrolytic polishing-CNC machining metal part

Electrolytic polishing uses the part to be polished as the anode, the insoluble metal as the cathode, the two poles are immersed in the electrolytic cell at the same time, and the direct current is applied to generate selective anode dissolution, so as to achieve the effect of increasing the brightness of the part surface.Advantages of electro polishing :

1)The inner and outer surfaces have the same color and lustre, and the luster is long-lasting, and the recesses that cannot be thrown by mechanical polishing can also be leveled.

2)High productivity.

3)Increase the corrosion resistance of the part surface.

(Steel part with electrolytic polishing)

These are the common polishing methods, if you want to learn more about the surface finishing, please feel free to contact us.

Other news

- 1SuNPe Has Introduced Large Capacity for High Efficiency and Good Quality .

- 2Welcome you from SMART SUPPLY CHAIN and IDRAC BUSINESS SCHOOL

- 3The Safety Meeting and Fire Drill Activity at Headquarters of SuNPe

- 4The 2020 Friendly Football Match

- 5SuNPe and Wuyi University start Technical Cooperation

- 616 Sets of New CNC Machines Were Introduced into SuNPe

- 7Interchangeable inserts for Injection Molding Project

- 8SuNPe Sanya Team Building Trip 2020

- 9Choosing the Right Injection Molding Tooling Material for your project

- 10Congratulations!SuNPe Have Full Successful Annual Party For 2018.