How to solve the deformation of your prototype and low volume products?

How to solve the deformation of your prototype and low volume products?

1.What types of parts are easily deformed?

Deformation is a common problem in manufacturing. For CNC machining and sheet metal, parts long and thin, no rib support parts will be deformed easily. For injection molding, the wall thickness is too thick or uneven will also cause shrinking deformation.2.What materials are easily deformed?

In CNC prototype and injection molding production, like POM, HDPE, PE, PP are relatively easy to deform.3.How to solve the deformation of CNC parts, vacuum casting parts, sheet metal parts, and injection molding parts?

1)CNC machining part

In CNC machining, due to material, structure reasons, as well as wall thickness problems, will cause part deformation.

For materials which are easily deformed, we first perform rough CNC machining on the material, and finish the rough outline of the part. Then it is placed to completely remove the stress, then fine CNC machining.

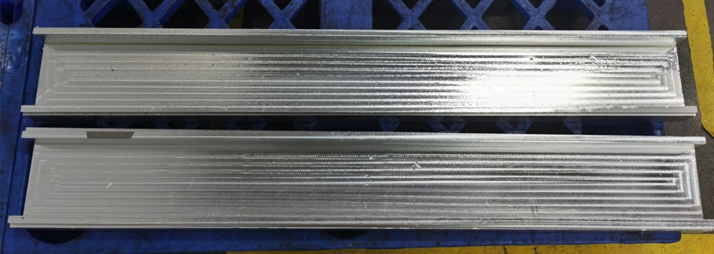

(Aluminum parts are placed after CNC rough machine to remove stress)

If the side wall of the part is very thin, the thickness can be reserved according to the structure of the part, we can also add ribs to help machining.

CNC machining with PP

Add rib position to prevent deformation.

We're manually remove the rib in the middle.

2) Vacuum casting part

For vacuum casting part, we need to determine the shrinkage ratio for scaling comparison when making the CNC master. Different materials have different shrinkage rates. Shrinkage also depends on the structure and thickness of the part.

For example, the material PU8150, which is similar to ABS, has a uniform wall thickness within 3mm thickness and a shrinkage rate of 0.3%.PU8400, the material is similar to an elastomer, and its shrinkage is related to the hardness required by the customer.

High hardness: the larger shrinkage.

Low hardness: the smaller shrinkage.

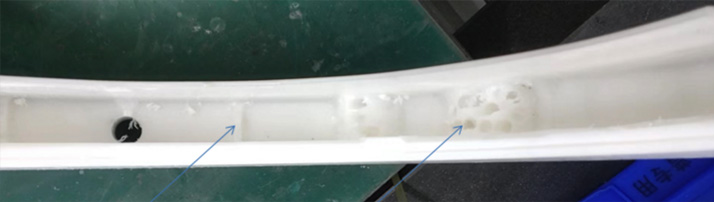

When the shrinkage rate is set and the product is casted, the part is still deformed. How do we solve it?

We improve the deformation by secondary curing the parts, that is, put the parts into the silicone mold, or some features need to be fixed by making pins and fixtures, and then put them in the oven for curing.

Rapid mold, Silicone curing

3)Sheet Metal part

How to improve sheet metal deformation?

(1)Metal sheet: It is deformed due to its thin wall, and we improve the deformation by flattening it with a leveling machine.

(Before) (After)

(2)Bending parts: If the part is long, thin and also bent, the flatness and straightness may be deformed out of tolerance. We will modify the mold by evaluating the amount of deformation.

(3)The proper welding sequence needs to be selected. For welded structures with many parts, the parts should be welded and corrected individually, and then the entire weld assembled.

(4)To choose a reasonable welding method. Sheet metal fabrication welding methods have different energy densities and heat inputs. We will evaluate the appropriate welding method according to our customer's requirements, such as the amount of force and the acceptable deformation range.

(Sheet Metal part- welded assembly)

4) Injection molding part

Reasons for deformation of injection molding parts:

(1) Materials that are easily deformed, such as: PP, POM, PE, PVC, Nylon+GF%.

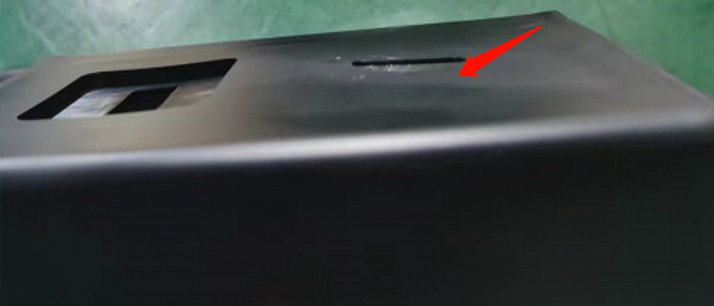

(2) The wall thickness of the part is too thick, or the wall thickness is uneven (usually the wall thickness of injection molding is 2.5-5mm, but the specific analysis needs to be carried out according to the product design structure and material).

The following are methods of improving deformation:

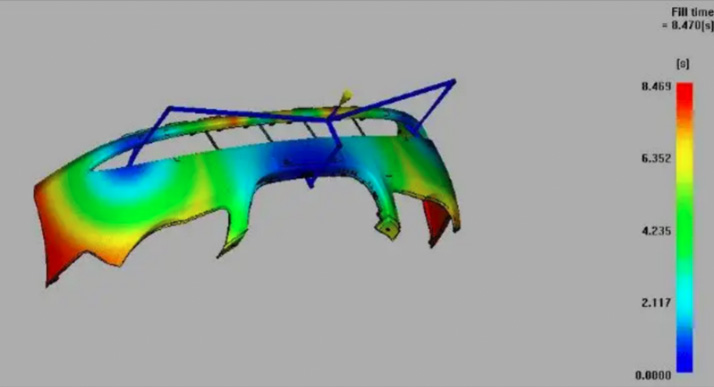

(1) We do mold flow analysis before production to get the amount of deformation, and consider reverse deformation when making molds. This is the most common and correct way for volume production.

(Mold flow analysis)

(2)Adjust the injection parameters to improve the deformation, such as adjusting the holding time and holding pressure, and the mold temperature and so on.

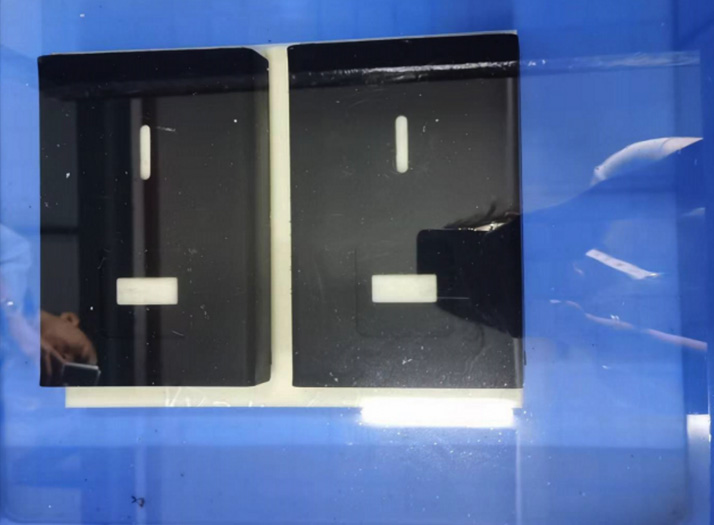

(3)Make a fixture fixation + cold water device, which is suitable for low-volume production.

(Injection molding deform part: Uneven wall thickness, no rib support, shrinkage)

(Fixture fixed + cold water device to improve deformation)

SuNPe can help you solve the problem of deformation in prototypes and low-volume products. For CNC parts, they can be improved by removing stress. For the vacuum casting parts, they can be improved by secondary curing. For the sheet metal and injection molding parts, they can be improved by evaluating the amount of deformation and changing the mold, and the specified fixture can be produced to improve the deformation as well.

Please feel free to contact us to learn more about how to solve deformation problems.

Other news

- 1A Huge Staff Birthday Party in October

- 2Congratulations!SuNPe Have Full Successful Annual Party For 2018.

- 3The import of MasterCAM 2020 5-axis software

- 4Do you know that SuNPe can provide ultrasonic welding service?

- 5Anodizing finishing at SuNPe

- 6Technical Training for 5-Axis CNC Machining

- 7What Makes SuNPe Be Outstanding In Quality Control?

- 816 Sets of New CNC Machines Were Introduced into SuNPe

- 9The Annual Sales Meeting and Badminton Activity

- 10Plastic ultrasonic welding service at SuNPe.