Anodization is available at SuNPe for Aluminum parts

Anodization is available at SuNPe for Aluminum parts

What is role of anodization of prototype and production?

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts,and anodizing gives the part additional durability, and a more attractive finish.The process is ideal for several materials, however, the most important and commonly used one is aluminum nowadays and at SuNPe.What kinds of anodization can do at SuNPe?

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts and SuNPe does well job in TYPE I Chromic Acid Anodize, TYPE II Sulfuric Acid Anodize and the Type III Hardcoat Anodize.After anodization,we can also engrave or machining part marks on part surface.Cleaning and Pre-treatment

Before anodization,SuNPe will get parts machined and have roughly clean or smooth, brush or even bead blasted,etc to have fine finish as per customers request

Anodizing

After pre-treatment, the product is ready for anodizing. As mentioned above, sulfuric acid is the go-to electrolyte for aluminium anodizing. Alternatives that are sometimes used are organic acid,phosphoric acid, and chromic acid.

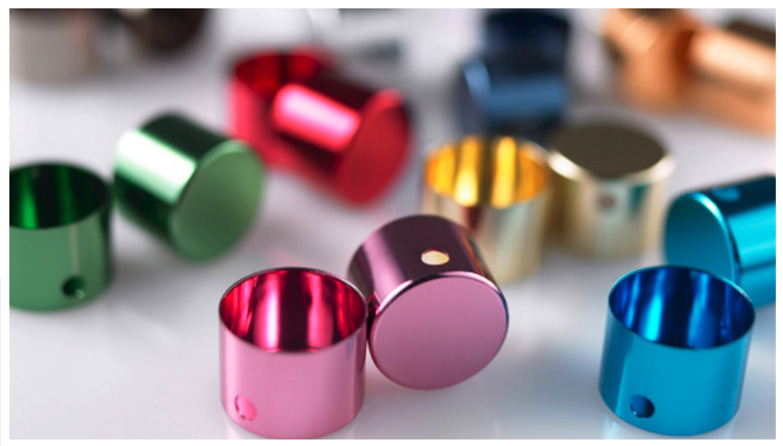

Coloring

Dyeing is the popular method of adding colour to an anodized aluminium product. The pores that are formed during the electronic chemical process readily absorb dies or pigments.

Sealing

Sealing is the final step in the aluminium anodizing process. This prevents water leakage and improves corrosion resistance

Project Cases

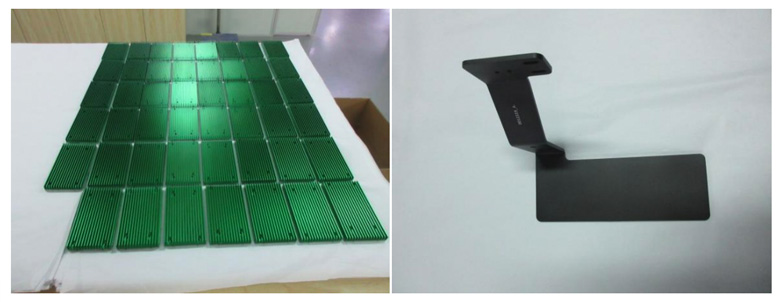

SuNPe does lots of anodization work for the Aluminum projects made by CNC machining or sheet metal services and etc.

Anodizing for CNC parts (Left picture)and Sheet metal parts(Right picture)

SuNPe offers TYPE II Sulfuric Acid Anodize

As in TYPE II Sulfuric Acid Anodizes, SuNPe has its focus on providing a nice aesthetic finish first and also providing protection through the oxide layer and the thickness will be between 10µm and 20µm.If your projects requires better tolerance,we will suggest you to choose Type II anodization for you CNC or sheet metal parts.

Anodizing for CNC aluminium parts

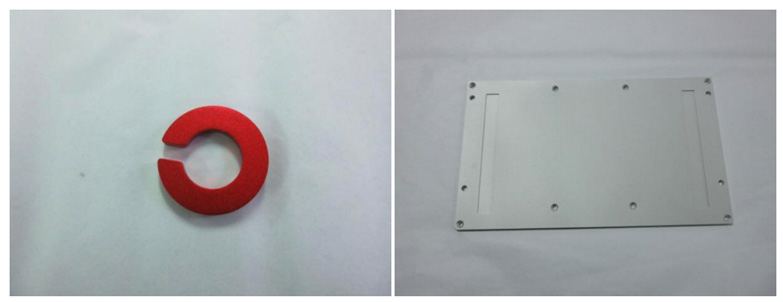

SuNPe offers Type III Hardcoat Anodize- Widely used for Functional applications

Type III hardcoat Anodize at SuNPe involves more demanding conditions to achieve harder coating and more resistant to part abrasion.In cases where we need superior protection of aluminium alloys (marine applications or exposure to corrosive chemicals), we recommend opting for hardcoat anodizing for you CNC or sheet metal parts.Usually the thickness of the oxidation hard coating will be between 25µm and 50µm.

Anodizing for CNC aluminium parts

Benefits of Anodizing

Anodizing is a high-quality and affordable finishing process. Therefore, it is popular and used for a few applications across a wide variety of industries. And SuNPe has rich manufacturing experiences and had achieved lots of success in different industries.For example,

Digital products.Automotive.Architecture.Consumer goods.Home application,etc.

Please feel free to contact us to know more about Aluminum Anodizing at SuNPe.

Digital products.Automotive.Architecture.Consumer goods.Home application,etc.

Please feel free to contact us to know more about Aluminum Anodizing at SuNPe.

Other news

- 1SuNPe Wishes You And Your Family A Happy Mid Autumn Festival!

- 2Embrace New Age•Obtain New Thoughts•Build New Future——SuNPe Group New Year Party in 2020

- 3The 2020 Friendly Football Match

- 4SuNPe continues to promote 5S management

- 5The 2017 Friendly Basketball Match for HuiZhou Commercial Union of ZhongShan

- 616 Sets of New CNC Machines Were Introduced into SuNPe

- 7New Plant, New Images of SuNPe

- 8Improve ourselves, improve our service -- training and developing of management

- 9Drager X-Act 7000 project at SuNPe

- 10SuNPe Wishes You A Happy Chinese New Year In 2021