Do you know that SuNPe can provide ultrasonic welding service?

Do you know that SuNPe can provide ultrasonic welding service?

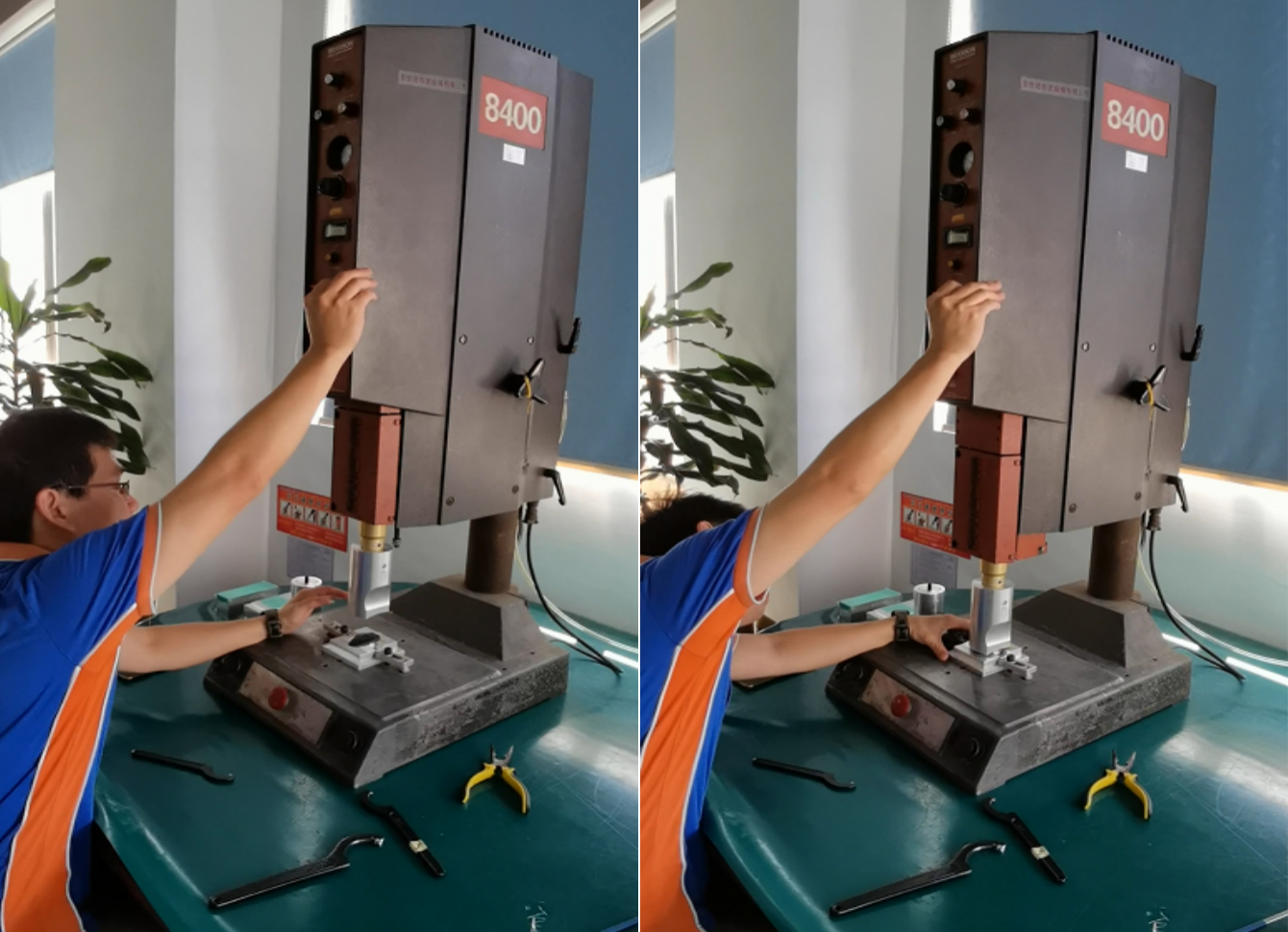

SuNPe can provide ultrasonic welding services.

Ultrasonic welding is very helpful for projects that require waterproofing, airtightness, and appearance products. SuNPe has successfully used this process in the submersible tracker project.

Ultrasonic welding is a fast, clean, and effective assembly process for assembling and processing thermoplastic plastic parts and some composite components. It is currently used for bonding between plastic products, bonding between plastic products and metal parts, and bonding between other non-plastic materials.

Ultrasonic welding is to transfer ultrasonic energy to the welding area through the upper weldment. Because the welding area, that is, the acoustic resistance at the interface of two weldings, will generate local high temperature. In addition, due to the poor thermal conductivity of the plastic, it cannot be distributed in time for a while, and it gathers in the welding area, causing the contact surface of the two plastics to melt rapidly, and after a certain pressure is applied, they are merged into one.

Advantages of ultrasonic welding:

1.Ultrasonic welding will not produce the toxicity such as chemical agents.

2.No need to add any adhesive, and the operation is simpler and faster.

3.It can be welded to the joint surface through media such as water and oil.

4.The welding effect can achieve air-tight and liquid-tight sealing effects.

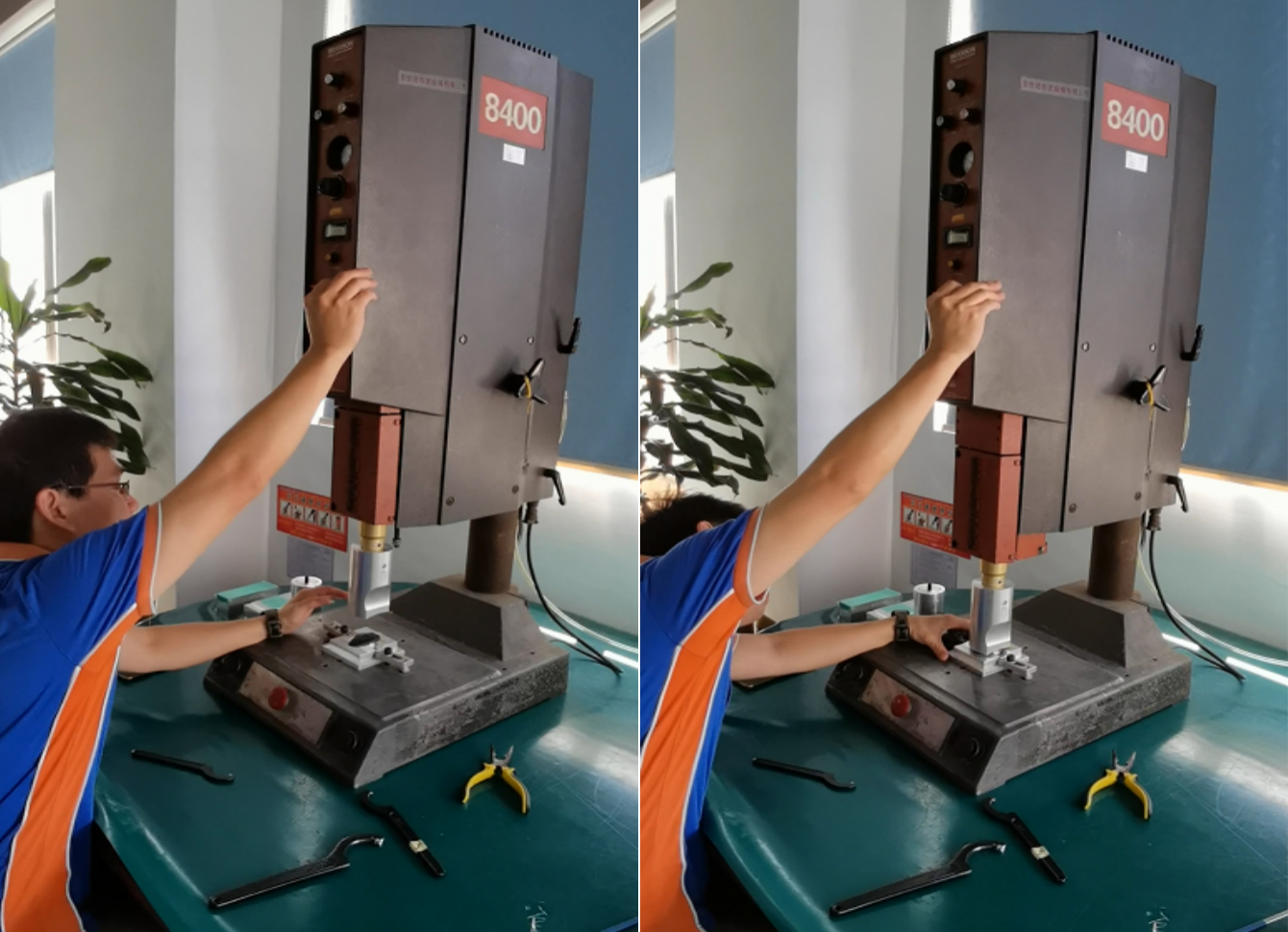

Ultrasonic welding is very helpful for projects that require waterproofing, airtightness, and appearance products. SuNPe has successfully used this process in the submersible tracker project.

Ultrasonic welding is a fast, clean, and effective assembly process for assembling and processing thermoplastic plastic parts and some composite components. It is currently used for bonding between plastic products, bonding between plastic products and metal parts, and bonding between other non-plastic materials.

Ultrasonic welding is to transfer ultrasonic energy to the welding area through the upper weldment. Because the welding area, that is, the acoustic resistance at the interface of two weldings, will generate local high temperature. In addition, due to the poor thermal conductivity of the plastic, it cannot be distributed in time for a while, and it gathers in the welding area, causing the contact surface of the two plastics to melt rapidly, and after a certain pressure is applied, they are merged into one.

Advantages of ultrasonic welding:

1.Ultrasonic welding will not produce the toxicity such as chemical agents.

2.No need to add any adhesive, and the operation is simpler and faster.

3.It can be welded to the joint surface through media such as water and oil.

4.The welding effect can achieve air-tight and liquid-tight sealing effects.

Other news

- 1Fighting for the dreams, Nothing is impossible——SuNPe Outdoor Training Program

- 2Brought in New machines in October 2020!

- 3Award of Merit for School Development Support

- 4Interchangeable inserts for Injection Molding Project

- 5The third basketball league of SuNPe Group in 2020

- 6SuNPe Wishes You A Happy Chinese New Year In 2021

- 7SuNPe Annual Sales Teams Christmas Activities

- 8What are the applications of EDM machining at SuNPe?

- 9How many polishing methods in the surface finishing?

- 10Formnext 2023 exhibition invitation from SuNPe Prototype at Booth 110-F37