3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

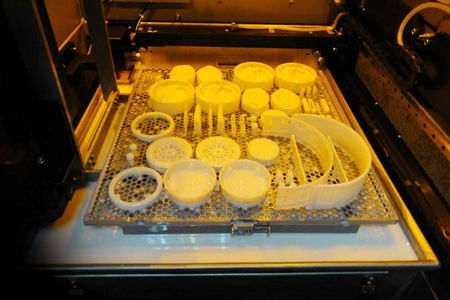

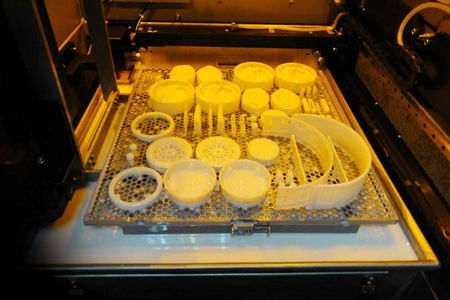

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

Simply, 3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine.

At SuNPe, we can not only CNC machine metal, plastic or other materials, but also professional in 3D printing from various materials, using different processes such as:

⦁Stereolithography(SLA)

⦁Selective Laser Sintering (SLS)

⦁Digital Light Processing(DLP)

⦁Multi Jet Fusion (MJF)

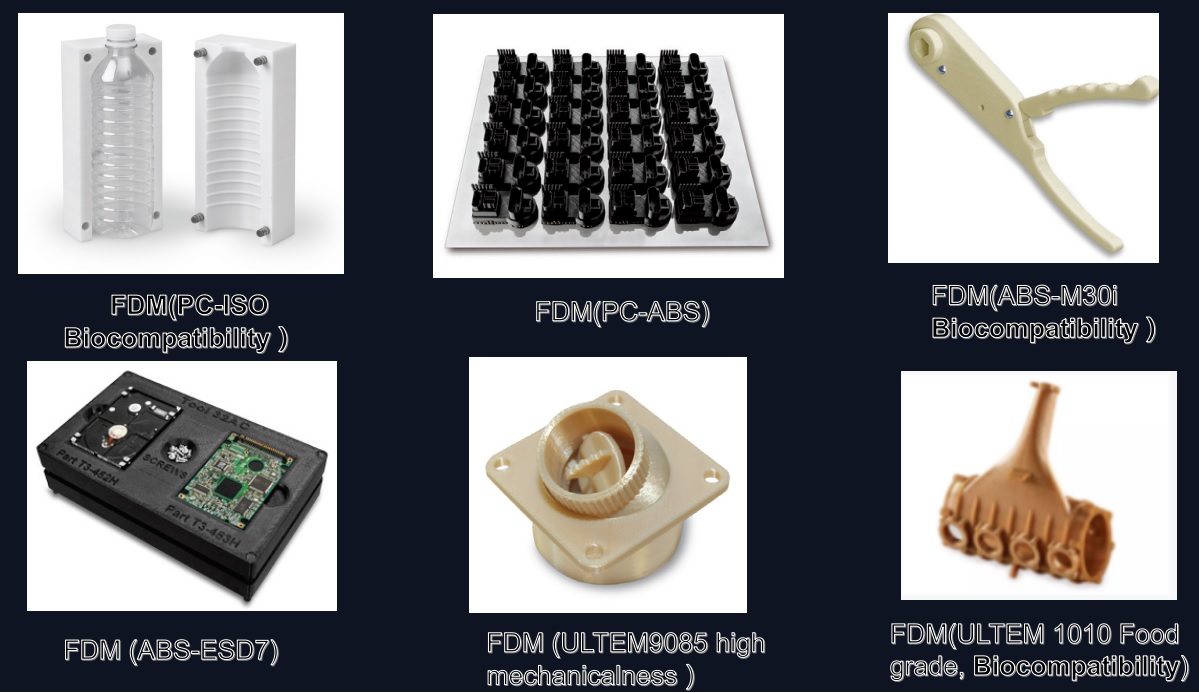

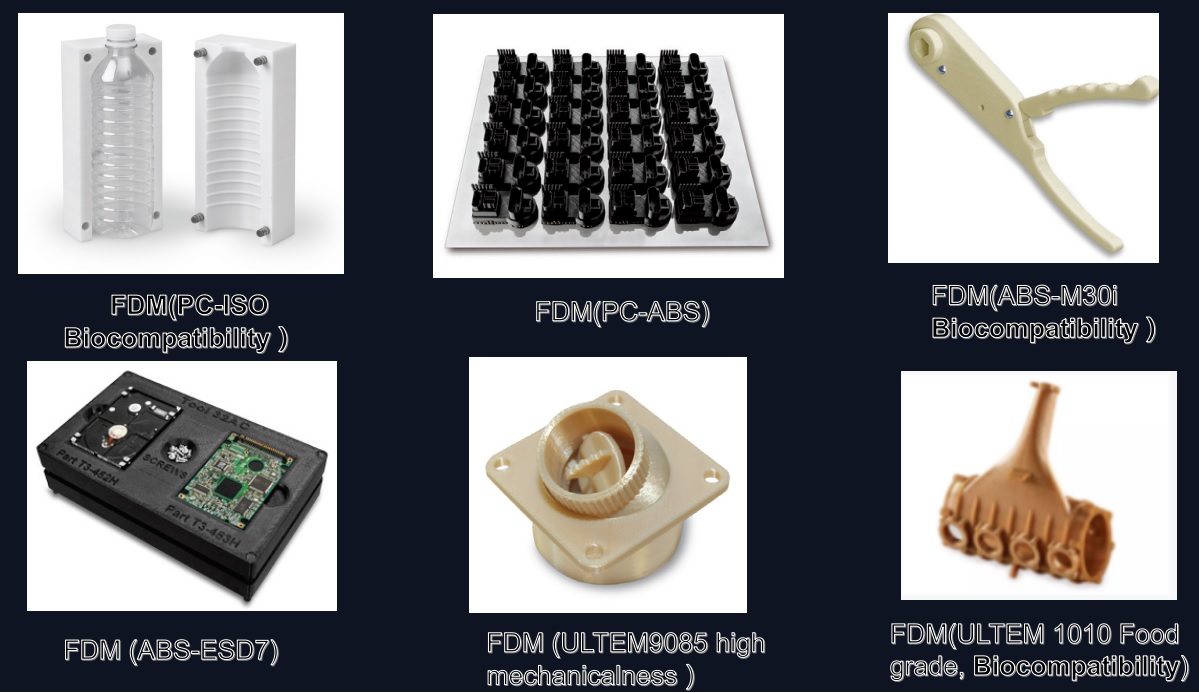

⦁Fused Deposition Modeling (FDM)

⦁Polyjet

⦁Metal printing, etc......

3D printing industry

3D printing encompasses many forms of technologies and materials as 3D printing is being used in almost all industries you could think of.

A few examples of the industries it can be used:

-Consumer products(design,footware,eyeware, furniture,etc)

-Electrical products, home appliance(cases,

-Industrial products(manufacturing tools, prototypes, functional end-use parts)

-Architectural scale models & maquettes

-Medical products or equipment

Advantages of 3D printing

-Fast lead time and relatively cheap

-Multiple material choices

-Customizable, easy to operate and control

-Sustainable development, less waste

-High accuracy

Don't know how to make a real product or make your design realizable? Contact SuNPe to let us know your ideas and provide you with the best solutions.

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

Simply, 3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine.

At SuNPe, we can not only CNC machine metal, plastic or other materials, but also professional in 3D printing from various materials, using different processes such as:

⦁Stereolithography(SLA)

⦁Selective Laser Sintering (SLS)

⦁Digital Light Processing(DLP)

⦁Multi Jet Fusion (MJF)

⦁Fused Deposition Modeling (FDM)

⦁Polyjet

⦁Metal printing, etc......

3D printing industry

3D printing encompasses many forms of technologies and materials as 3D printing is being used in almost all industries you could think of.

A few examples of the industries it can be used:

-Consumer products(design,footware,eyeware, furniture,etc)

-Electrical products, home appliance(cases,

-Industrial products(manufacturing tools, prototypes, functional end-use parts)

-Architectural scale models & maquettes

-Medical products or equipment

Advantages of 3D printing

-Fast lead time and relatively cheap

-Multiple material choices

-Customizable, easy to operate and control

-Sustainable development, less waste

-High accuracy

Don't know how to make a real product or make your design realizable? Contact SuNPe to let us know your ideas and provide you with the best solutions.

Other news

- 1Self-Challenge, Self-Improvement

- 2Award of Merit for School Development Support

- 3Choosing the Right Injection Molding Tooling Material for your project

- 4SuNPe Organized 2018 Campus Commonweal Activities --Hand in hand, for love

- 5How to solve the deformation of your prototype and low volume products?

- 6SuNPe Organized 2019 Charity Activity --- Grow with Love, grow with SuNPe

- 7The First Shipment After The Labour Holiday!

- 8The Annual Sales Meeting and Badminton Activity

- 9SuNPe Has Strict Packaging Requirements

- 10Warmly welcome the students from MIT.