Vacuum Casting Is One Of Most Advantages Service at SuNPe

Vacuum Casting Is One Of Most Advantages Service at SuNPe

If you're seeking the supplier who can implement your design with vacuum casting. We think SuNPe can provide a range of material options and techniques to deliver the finest vacuum casting. Looking at the overall picture, vacuum casting is an effective alternative to 3D printing and injection molding. Taking into account processing time and cost, complexity of parts required, surface finish, quantity, and delivery time. When you consider all of these important aspects, it is clear that vacuum molding has more to offer than 3D printing and injection molding.

Vacuum casting is one of the most popular options for creating prototypes in manufacturing. The use of technology must be proven to be extremely beneficial.

Some common markets for rapid use of vacuum casting include the following:

● Rapid plastic prototype;

● Medical industry: Prosthetics and medical devices;

● Aerospace Manufacturing;

● Automotive: Car doors, Car interior components, Side Mirror, etc.

● Robotics: Body, internal components.

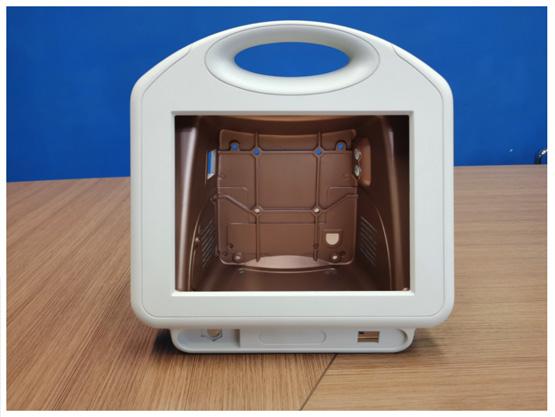

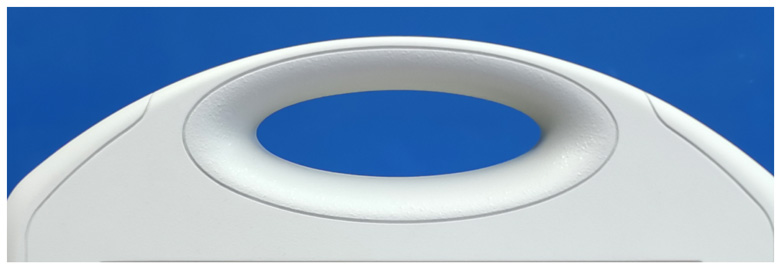

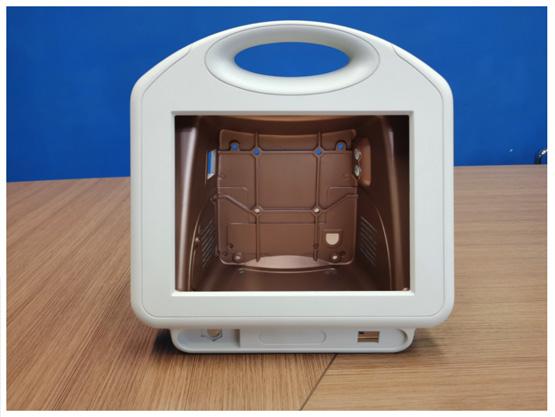

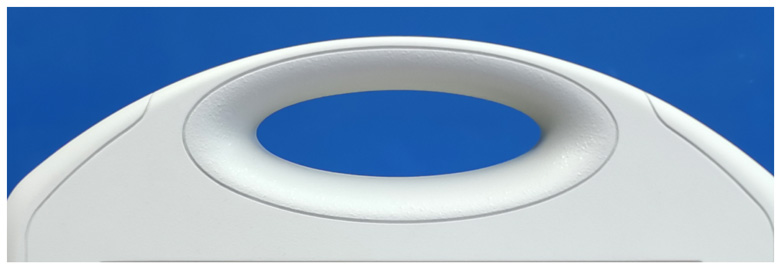

Due to the wide availability of plastic materials, vacuum casting is widely used in the medical industry. SuNPe made a low-volume casting production of medical device for our customer, they need 50-100 sets per year.

● Material: We used PU8260(UL94V0) for this medical device, it's flame retardant material which is safe to use in medical filed.

● Surface texture: The texture of product was done on the master model and silicone mold. It will be casted on the product directly.

● Surface finish: After vacuum casting, due to the customer has high requirements on the surface, that we painted the out surface with two-component painting. It's durable for using alcohol. For the inter surface, we painted with EMI shield painting. It's conductive (anti static) and static dissipative grades for use on products.

The product made by vacuum casting is no different from the final product.

In the development of a product must go through from prototype to mass production. When your design is unstable, but you need small batch products for testing. And the cost rapid tooling is high and difficult to revise the mold. This is where vacuum casting can play an important role in your project.

Vacuum casting has extensive benefits for rapid prototype and low-volume production. SuNPe has supported hundreds of companies to get the high quality urethane parts. Welcome send your CAD files now to get a free quotation.

E-mail: sales@sunpe.com

What fields and uses can vacuum casting be used in?

Vacuum casting is one of the most popular options for creating prototypes in manufacturing. The use of technology must be proven to be extremely beneficial.

Some common markets for rapid use of vacuum casting include the following:

● Rapid plastic prototype;

● Medical industry: Prosthetics and medical devices;

● Aerospace Manufacturing;

● Automotive: Car doors, Car interior components, Side Mirror, etc.

● Robotics: Body, internal components.

Due to the wide availability of plastic materials, vacuum casting is widely used in the medical industry. SuNPe made a low-volume casting production of medical device for our customer, they need 50-100 sets per year.

● Material: We used PU8260(UL94V0) for this medical device, it's flame retardant material which is safe to use in medical filed.

● Surface texture: The texture of product was done on the master model and silicone mold. It will be casted on the product directly.

● Surface finish: After vacuum casting, due to the customer has high requirements on the surface, that we painted the out surface with two-component painting. It's durable for using alcohol. For the inter surface, we painted with EMI shield painting. It's conductive (anti static) and static dissipative grades for use on products.

The product made by vacuum casting is no different from the final product.

What stage of the project can be used Vacuum casting?

In the development of a product must go through from prototype to mass production. When your design is unstable, but you need small batch products for testing. And the cost rapid tooling is high and difficult to revise the mold. This is where vacuum casting can play an important role in your project.

Vacuum casting has extensive benefits for rapid prototype and low-volume production. SuNPe has supported hundreds of companies to get the high quality urethane parts. Welcome send your CAD files now to get a free quotation.

E-mail: sales@sunpe.com

Other news

- 1Capabilities For Injection Mold Enlarge Again!

- 2What is over-molding?

- 3Types of Spline manufacturing at SuNPe

- 4Amazing 3D Printing Project for Senturionkey's Luxury Exhibition Hall

- 5Competition promotes progress!

- 6Quality is everything at SuNPe-Weekly Quality Meeting

- 7How to solve the deformation of your prototype and low volume products?

- 816 Sets of New CNC Machines Were Introduced into SuNPe

- 9SuNPe's Work Resumption During the COVID-19

- 10SuNPe Wishes You And Your Family A Happy Mid Autumn Festival!