What is welding?

Welding is a fabrication process that uses heat, pressure, or both to fuse two or more parts together, forming a joint as the parts cool. It is typically used on metals and thermoplastics, commonly used across a range of industries including aerospace, automotive, energy and construction.Welding services at SuNPe

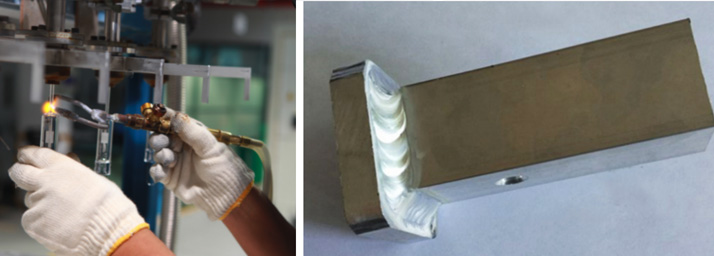

At SuNPe, we can work with many different materials and welding processes. The common and special welding processes we can provide: such as arc welding, resistance welding, gas welding, induction welding, and laser welding etc. There are some popular welding processes at SuNPe:1)Arc welding: Arc welding is widely used in aerospace industry, automotive industry and precision work with its smooth welding, good impact strength, higher corrosion resistance, cost effective and environment friendly advantages.

2)Resistance welding: Resistance welding is the joining of metals by applying pressure and passing current for a length of time through the metal area which is to be joined. The key advantage of resistance welding is that no additional materials are needed to create the bond, which makes this process extremely cost effective.

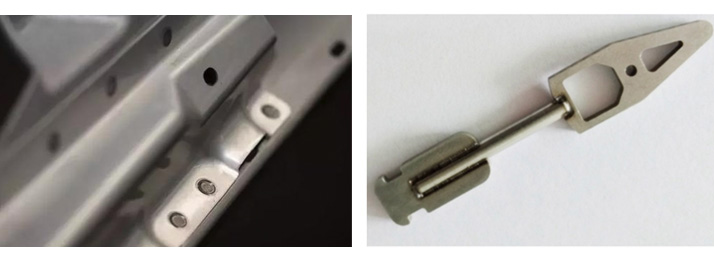

a)Spot welding is a popular resistance welding method. It is used extensively in the automotive industry—ordinary cars can have several thousand spot welds.

b)Seam welding is the joining of parts made of similar or dissimilar materials along a continuous seam. Seam welding has the advantage of creating clear welds with no gas formation or welding fume. It is normally to be found on various types of barrel and exhaust systems applications.

(Spot welding, automotive aluminum part) (Seam welding, sheet metal, medical component)

Few tips you should know about welding

1) Carbon content is related to weldability. Low carbon steel weldability is good to weld, middle carbon steel weldability is quite weak , while high carbon steel weldability is poor.

2) Generally, the material that easy to weld are: brass, bronze, copper, zinc and so on; And the alloy that is weak to weld are: copper alloy, iron nickel cobalt alloy, titanium and steel, etc. The alloys that difficult to weld alloys need to be took surface pretreatment measures, then choose the appropriate flux and welding process to help complete the welding task perfectly.

3) Galvanized materials can not be welded, because welding will destroy the galvanized layer, whichl lead to holes, cracks, or breaks, and aslso cause the weld brittle, rigid decrease.

4) When the material is thin, it is not easy to weld since it will make the parts breaks.

5) Welding of aircraft components is not recommended. The main material of the aircraft is Aluminum alloy with weak weldability. The local stress concentration in the welding area makes the metal brittle, and it is easy to cause defects such as sand holes, bubbles and cracks. When the aircraft flies at high altitude and high speed, it may make cracks more serious at the welding position and endanger safety when it works for a long time in such an environment.

If you have no idea whether your project can be weldable or not, how to choose the type of welding, please feel free to contact us, our professional team would love to help!

Other news

- 1Award of Merit for School Development Support

- 2How does SuNPe help with surface texture?

- 33D printing services at SuNPe

- 4Congratulations!SuNPe Have Full Successful Annual Party For 2018.

- 5Fire Drill at new factory of SuNPe, The escort of your projects!

- 6New Plant, New Images of SuNPe

- 7The First Shipment After The Labour Holiday!

- 8Comparison of Electroplating Chrome and Vacuum Chrome

- 9Keep Moving, Keep Thriving--SuNPe's Sales Team Activity in Hailing Island

- 10Quality is everything at SuNPe-Weekly Quality Meeting